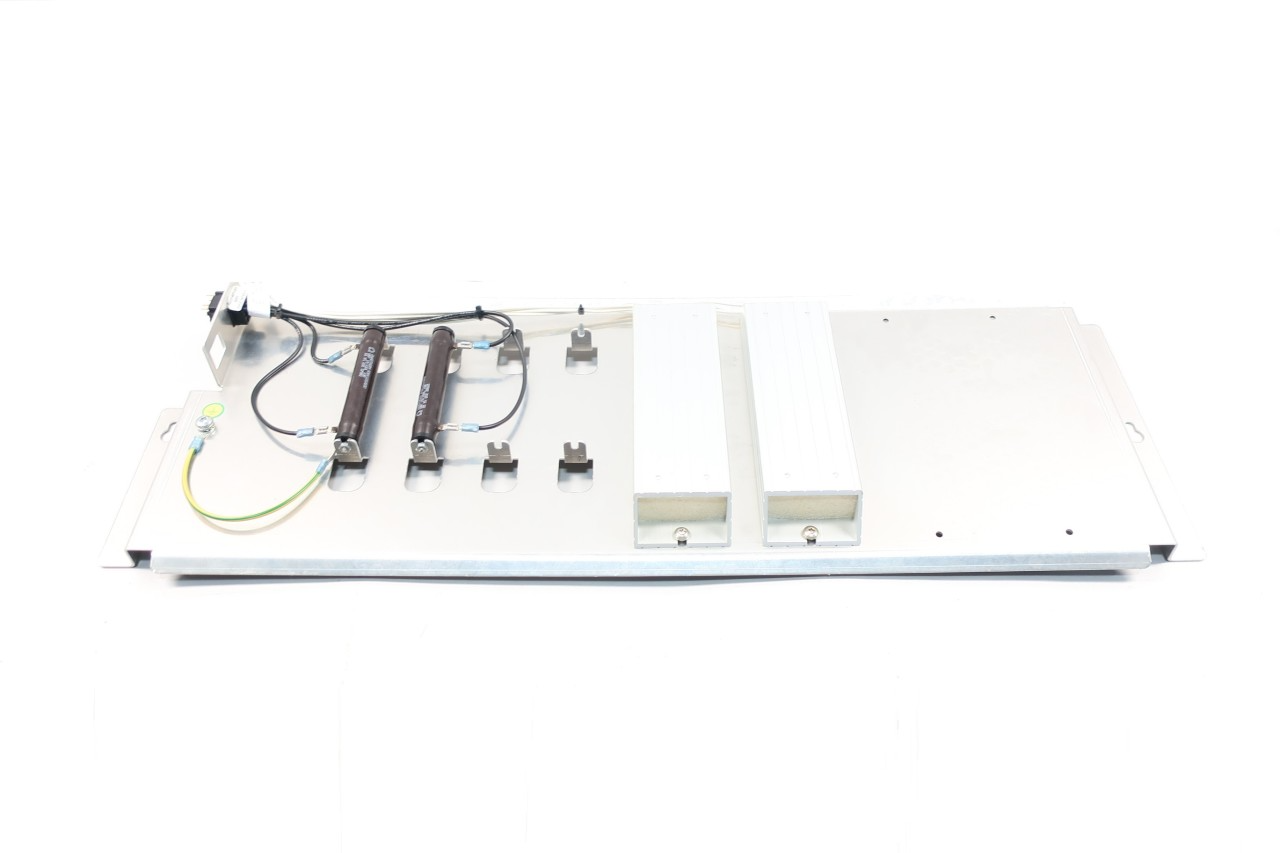

LAMP TRIGGER 101935-217

Welcome to AE Automation Auto Parts

Your trusted source for diverse PLC and automation components.

LAMP TRIGGER 101935-217: A Key Component in Electrical Engineering

The LAMP TRIGGER 101935-217 is renowned in the electrical engineering sector for its essential role in automation systems. As industries increasingly embrace automation, understanding the components that drive these systems is crucial. The LAMP TRIGGER 101935-217 stands out due to its efficiency, reliability, and versatility in various applications, particularly in industrial automation and renewable energy sectors.

Technical Specifications (IEC60947-2)

According to the IEC60947-2 standards, the LAMP TRIGGER 101935-217 meets rigorous safety and performance criteria. This standard outlines essential characteristics for devices used in industrial environments, ensuring they can handle electrical loads efficiently while providing necessary protection against faults.

- Voltage Rating: Typically designed to operate at standard industrial voltages, enhancing compatibility across different systems.

- Current Rating: Capable of handling high currents, making it suitable for various industrial applications.

- Temperature Range: Operates effectively in a wide temperature range, ensuring reliability under diverse environmental conditions.

- Protection Class: Features robust insulation and protection mechanisms to prevent short circuits and electrical failures.

- Compliance: Adheres to IEC60947-2 standards, ensuring high-quality performance and safety in electrical installations.

Applications in Industrial Automation

The applications of the LAMP TRIGGER 101935-217 in industrial automation are extensive. This component is primarily used in controlling lighting circuits and other electrical loads in automated systems. Its reliability ensures that machinery operates smoothly, minimizing downtime and enhancing productivity.

In manufacturing plants, the LAMP TRIGGER is often integrated into control panels, enabling operators to manage large arrays of equipment from a central location. This centralization not only improves efficiency but also enhances safety by allowing for easier monitoring and control of electrical systems.

Renewable Energy Applications

As the world moves towards sustainable energy solutions, the LAMP TRIGGER 101935-217 plays a pivotal role in renewable energy systems. It is commonly used in solar power installations to manage and control lighting and other electrical loads efficiently. By ensuring that these systems operate optimally, the LAMP TRIGGER contributes to the overall efficiency and reliability of renewable energy sources.

In wind energy systems, the LAMP TRIGGER can be used to control lighting for wind turbine operation and maintenance, ensuring that these installations can be safely accessed and serviced. The importance of effective lighting in ensuring worker safety in these environments cannot be overstated.

Conclusion

In conclusion, the LAMP TRIGGER 101935-217 is an invaluable component in the field of electrical engineering, particularly within industrial automation and renewable energy applications. Its compliance with IEC60947-2 standards underscores its reliability and effectiveness. As industries continue to advance towards automation and sustainability, components like the LAMP TRIGGER will be essential in driving these innovations.

For more information about various automation components, visit plcautoparts.com. Additionally, if you’re looking for further insights into electrical standards and best practices, check out the International Electrotechnical Commission for comprehensive resources.